By Kim Schmidt, Executive Editor

For over 35 years, members of the American Society of Agricultural and Biological Engineers (ASABE) have recognized and honored the most innovative advancements in engineering in the areas of agriculture, food and biological systems with the AE50 Award. The Products selected save producers time and reduce cost and labor, all while improving safety.

To be eligible for the award, each development — which could be a component, machine, structure, system, end product or procedure — must embody the application of new technology or the innovative application of an older technology. The technology must be new to the entire industry, not to an individual company. Each year, an international panel of industry experts in technology, design and product development gather to evaluate the entries and select up to 50 products for recognition.

Kubota RTV-X1130 Utility Vehicle (No. 218)

Kubota’s new RTV-X1130 was designed with the new Pro-Konvert system to reimagine the capabilities of a traditional utility vehicle cargo bed with multiple, tool-less configuration options. The RTV-X1130 features a 6-foot long bed that has 3 drop-down sides and back tailgate, essentially converting it into a flat bed, along with the ability to divide into different sub-compartments for easy access and for handling various types of cargo, ultimately increasing ease of use and productivity. With the inclusion of a hydraulic dump bed and enhanced bed lock feature, users can now have greater control and safety over their cargo load and achieve precise material placement on the farm or ranch. The cargo bed has 26 cubic feet of storage and a cargo capacity of 1,212 pounds. It is constructed of heavy-duty steel and comes standard with a spray-on bed liner. “When we spent time with our customers, we noticed how often they were loading or unloading from the cargo bed as well as the number of customers utilizing our different Kubota model that has seating and cargo convertibility,” says Kubota’s Christine Schunk. “Loading and unloading were never at the top of the list with regard to customer complaints, but this perspective shift helped us uncover a really exciting and innovative enhancement. The ProKonvert functionality has been something that our dealers and customers have loved.”

Kubota Tractor Corp., Grapevine, Texas

www.KubotaUSA.com

Indigo Ag CLIPS Device (No. 219)

The CLIPS device is an innovative dry powder application system that holds a single sealed pod containing a flowable powder product, which “clips" to the interior of a bulk seed box and remains sealed until the seeds are released from the bottom of the seed box at the time of planting. CLIPS simplifies the process to treat corn and soybean seeds with flowable powder biologicals products by integrating the treatment process with the bulk storage and delivery of seeds — the seed box container — enabling biologicals to be “applied” on seed up to 2 years in advance with no the retailer or the farmer. CLIPS provides fast, reliable application of dry powder formulations, while sidestepping restrictive on-seed stability and planting window concerns. “We have shown through over 370 seed samples from 2 different test locations that the application of Indigo’s dry flowable product through the CLIPS system results in an even seed coating on par with or better than manual application methods without additional steps or the need to account for planting windows,” says Kevin Calzia with Indigo Ag. “In addition to the core benefit of improved biological seed treatment, we completed a beta-test of CLIPS during the Spring 2024 planting season to collect early customer feedback.”

Indigo Ag Inc., Boston, Mass.

www.IndigoAg.com

PTx Trimble OutRun (No. 220)

OutRun enables a tractor pulling a grain cart to operate without a driver during harvest. It comes as a self-contained kit, supports existing decade old tractor models, and allows farm operations to maintain or increase productivity when labor is hard to find. “OutRun lets farms maintain or improve productivity despite the unavailability of labor,” says PTx Trimble’s Dinen Subramaniam. “For example, one person harvesting a field (driving back to the headlands to unload) is expected to be close to 65-75% less efficient than that person harvesting with the help of OutRun. Similarly, a 2-person operation harvesting with OutRun is expected to be 40-50% more efficient than those two people harvesting by themselves.” Using an intuitive interface, a combine operator can stage or position a grain cart around the field. When summoned to unload a combine, the grain cart autonomously comes to, matches speed and distance to the combine, allowing for unloading on the go. The combine operator can send the grain cart to a predefined truck unload zone, where the unload is performed. OutRun navigates around the field avoiding unharvested land, reusing previously traveled paths to reduce compaction. OutRun uses its own communication infrastructure to reliably operate regardless of available cellular coverage at the field, ensuring high uptime during the critical harvest period.

PTx Trimble, Westminster, Colo.

www.PTxTrimble.com/outrun

Precision Planting ReconBlockage for Strip-Till (No. 221)

A blocked run on your strip-till bar can cost time and money. Using acoustic sensors to detect flow variance by section, ReconBlockage instantly alerts you of blocked runs, preventing skips and associated yield loss. Acoustic sensors work like a stethoscope, preventing issues with buildup that can plague optical sensors; the acoustic sensors signal is processed and sent to an iPad app, alerting the operator to issues with fertilizer flow. The sound that the sensor hears travels down an auditory tube to an ECU, where the sound is interpreted. From there, the gateway wirelessly connects to an iPad in the cab. “When applying banded fertilizer, farmers need to know that they are applying properly on each row,” says Precision Planting’s Bryce Baker. “A row that is not applying properly has a direct impact on the yield potential of the seeds planted in the row. With optical sensors used to sense fertilizer, there is the possibility that dust in the fertilizer mix or other issues in the sensing area can cause the optics to read incorrectly and cause erratic and/or incorrect readings, leading the operator to either a false confidence or chasing issues that do not exist.”

Precision Planting, Tremont, Ill.

www.PrecisionPlanting.com

Yokohama TWS Trelleborg TM1 ECO Power (No. 222)

The TM1 ECO Power is a new cutting-edge tire solution that combines sustainability, low rolling resistance, superior comfort, and high traction on hard soil. With its components sourced from sustainable materials, this product not only meets environmental needs but also delivers exceptional performance, says Yokohama’s Norberto Herbener. As agriculture evolves, the demand for greater efficiency and sustainability is growing. The new TM1 ECO Power tire, with its unparalleled and ultra-low rolling resistance, maximizes battery usage and reduces fuel consumption. “The advanced tire design ensures superior traction on hard soil, enhancing stability, tractor control, maneuverability and operator safety,” Herbener says. “This results in 26% lower slippage compared to premium standard agricultural tire. This also results in a fuel consumption savings of 3%.

Yokohama TWS, Wakefield, Mass.

www.Trelleborg-Tires.com

Salford Precision Row-Crop Cultivator (No. 223)

Salford’s Row-Crop Precision (RCP) Cultivator combines Salford durability with the most advanced row-crop cultivator technology, says Kendal Doerksen. The RCP’s innovative sweep design allows for cultivation speeds of up to 12 mph which significantly reduces the time required to complete each cultivation pass. The RCP features cutting edge camera row guidance technology to accurately detect crop rows, working with the 20-inch side shift system to avoid crop damage. The RCP offers section control as standard feature that automatically lifts rows based on a coverage map. This reduces potential crop damage on headlands and point rows. The RCP row units easily adjust to adapt to changing crop conditions. Hydraulic down pressure ensures each row remains engaged, and separate down pressure adjustments can be made for wheel track rows to combat compaction in these areas. All adjustments can be controlled through the in-cab display, giving operators complete control over their cultivation practices.

Salford Group Inc., Salford, Ont.

www.SalfordGroup.com

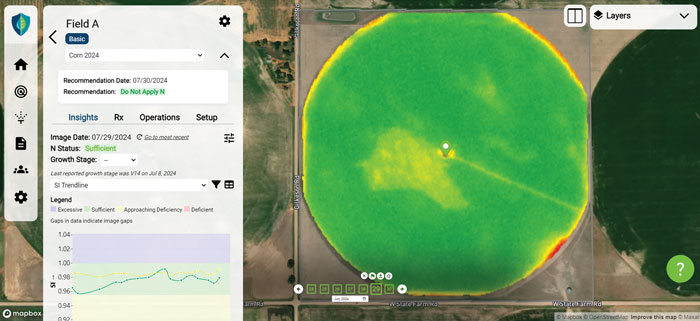

Sentinel Fertigation N-Time Advanced (No. 224)

N-Time Advanced software analyzes multi-spectral satellite images to deliver nitrogen application scheduling and variable rate recommendations for agronomists and farmers throughout the growing season. Image-based variable rate nitrogen application maps derive spatially appropriate rates for zones derived from imagery using calibrated nitrogen sufficiency values for each pixel in the field image. Rates are adaptive to crop growth stage and require little data to be delivered accurately. These variable rate maps can be used for either sidedress or fertigation. Rates can also be summarized at a field-level to adapt for farmers who don’t have or don’t see a benefit to variable rate applications. According to Sentinel Fertigation’s Jackson Stansell, on-farm research trials leveraging N-Time Advanced’s scheduling capabilities have demonstrated $25 per acre profitability improvements and 30% N use efficiency improvements versus standard grower management. N-Time Advanced is available to users throughout the U.S. through their web browser or mobile device.

Sentinel Fertigation, Ithaca, Neb.

www.SentinelFertigation.com

New Leader NL720 Fertilizer Spinner Spreader (No. 225)

The NL720 is a high efficiency, high precision, high output, widespread fertilizer spinner spreader. Precision and accuracy are achieved by controlling the granular product from the bin to the patented material delivery and spinner system. The spinner system is composed of multiple independent chutes to precisely control the material to the spinner disc. This allows for better control of the pattern shape and width. “The 120-foot spread produces a 33% increase in acres covered per hour while throughput increases 25% over leading spreaders for unrivaled efficiency,” says New Leader’s Benjamin Boelter. A new advanced and intuitive control system allows the focus to be on spreading not setup. No manual adjustments are made anywhere on the spreader. Maintenance is low with zero grease points and tool free removal of components. The entire spreader was a ground up design to ensure no compromises were made when looking at the precision or performance of the spreader.

New Leader, Cedar Rapids, Iowa

www.NewLeader.com

MacDon R1 FR (No. 226)

MacDon’s R1 FR offers the industry’s widest front-mounted rotary disc header to a tractor 3-point hitch system. This design matches current production systems by maintaining 16- or 13-foot cut widths to maintain operational logistics with common raking and merging practices. The R1 FR also allows for doubled productivity of a single power unit when paired with a MacDon R1 pull-type rotary header to provide up to an impressive 32 feet of cutting width. MacDon’s R1 FR is offered with the industry’s widest steel inter-meshing rollers to handle crop dry-down requirements, says MacDon’s Garrett Malkowich. With a full-width baffle mounted to the conditioner and protective forming shields, the FR can provide a narrow 5-foot windrow fitting under the tractor’s tires.

MacDon Industries, Winnipeg, Man.

www.MacDon.com

Firestone Ag Bridgestone VX-TRACTOR Tire (No. 227)

The VX-TRACTOR tire from Firestone Ag was engineered for operations traveling significant distances or constantly hauling between field and storage, plus custom operators and delivers 45% more wear life. This is due to up to 20% more lug volume and a new triple-defense compound, for excellent wear resistance, protection against stubble and durability, according to Bill Durivage with Firestone Ag. Wide, overlapping lugs increase stable contact and reduce travel vibration at the 40-mph speed rating, crucial for fast on-road transport. “The robust casing is rated at 32 psi, to carry heavy loads, while the flexible, durable sidewall provides smooth travel for operator comfort through varied terrain or road conditions,” he says. “Patented Involute lug design reduces slip and energy loss, for reliable traction in various soil conditions plus effective cleanout.”

Firestone Ag, Nashville, Tenn.

www.FirestoneAg.com

Claas of America Earlage Adapter (No. 228)

The New Claas Earlage Adapter couples a combine corn head to a Claas forage harvester. “This innovative product contributes lateral side to side contour of the head for precise ground following with large heads,” says Tyler Roucka. The drum on the earlage adapter is extra wide so it can more effectively move crops from the combine corn head into the narrower feed rolls of the forage harvester. The drum is bigger in diameter and closer to the feed rolls than others, which greatly reduces ear throw, but also tremendously increases capacity. The drum also floats up and down to move the crop more effectively to the feed rolls on the forage harvester. The adapter also converts the combine auto pilot so the Jaguar can read the signal. Deck plate adjustment can be adjusted from the multi-function handle from inside the Jaguar. Roucka says it has increased the capacity of the forage harvester by an average of 30% compared to other systems.

Claas of America, Omaha, Neb.

www.Claas.com

TeeJet FM9380 Electromagnetic Flow Meter (No. 229)

With industry-leading flow range, the TeeJet FM9380 flow meter offers tremendous flexibility, accuracy and reliability for field sprayers and fertilizer application equipment, says Rich Gould with TeeJet. Electromagnetic flow measurement offers high precision and requires no moving parts, which means no wear or maintenance. The advanced design of this flow meter results in an industry-leading flow range of 0.6-150 gallons per minute (GPM). The practical result of the wide flow range is the ability to accurately measure flow from a single nozzle to a full boom. The FM9380 offers convenient flanged liquid connections and convenient LED indicators to confirm power and flow status. Constructed from polypropylene and stainless steel, the FM9380 is compatible with most crop protection products.

TeeJet Technologies, Wheaton, Ill.

www.TeeJet.com

Walkabout Mother Bin 6000+ (No. 230)

A Walkabout Mother Bin is a fast discharge 6,000 bushel in-field mobile surge tank used to increase daily grain harvest productivity. A WMB is the difference between harvesting crop at near 100% efficiency vs. the accepted efficiency of just 60-70%. Typically, the combine with a full tank is stopped numerous times waiting for trucks whose arrival is unpredictable because of frequent delays at the elevator, says Layla Wieseler with Walkabout Mother Bins. On arrival, trucks are loaded via the WMB 900 bushel/minute auger and are back on the road within minutes, quickly clearing space for more freshly harvested grain. A new generation of high output combines (2,000+ bushels per hour) now stop regularly during the peak harvesting period because no empty grain trucks are present. A WMB breaks a long accepted grain harvest productivity bottleneck.

Walkabout Mother Bins LLC, Faulkton, S.D.

www.MotherBin.com

Innotag Distributors ISOBUS Row-Crop Cultivator Depth & Swath Control (No. 231)

“The need to provide a mechanical weeding alternative to farmers has become a reality with the newer weeds resistance to pesticide,” says Innotag’s Vincent Machabee.” In cases of high resistance, mechanical weeding will become the only option for weed removal.”

The row-by-row depth and swath control an innovative active force and swath control for row-crop cultivators. This system brings force control for maintaining ideal depth at high speeds, while also allowing for quick lifting of individual row units at the end of the row. The system can be installed from the factory on Innotag row-crop cultivators and also installed as an aftermarket upgrade on multiple models of existing row-crop cultivators. The user interface is compatible with ISOBUS displays and supports the task controller for automatic swath control. Control is done on a row-by-row basis, with each row unit having its own force measurement and adjustment. The system supports cultivators up to 24 rows with 25 row units.

Innotag Distributions Inc., Beloeil, Que.

www.Innotag.com

Bondioli & Pavesi E.D.I Driveshaft (No. 231)

EDI (Electronic Data Interchange) driveshafts are equipped with sensors and ECUs that can monitor the working parameters of the driveshaft, and transmit that data in real-time to improve productivity, reliability, maintenance and the operation of the complete tractor — driveshaft — implement system, according to Jon Cox with Bondioli & Pavesi. PTO driveshafts are now compatible with IoT and ready to communicate with the implement and the tractor. Sensors for torque, rotational speed, axial force and vibrations are available. The ECU can transmit and record this data, along with calculated power and joint angles. The data can be used for predictive maintenance or diagnostic functions. Operational limits can be set and monitored for improved efficiency and reliability. Communications to the tractor’s display can be done via CAN/ISOBUS connection. Mobile devices can connect via NFC or Bluetooth. Data may also be transmitted to a remote cloud service for remote access and storage.

Bondioli & Pavesi Inc., Ashland, Va.

www.Bondioli-Pavesi.com

MacDon FD261 FlexDraper (No. 233)

“At 61 feet wide with 50-inch deep drapers, this is the highest capacity FlexDraper MacDon has ever produced,” says Russ Henderson. Compared to the 50-foot FD250, the FD261 offers an additional 22% of overall productivity. The FD261 FlexDraper is a fully flexing 61-foot draper header. It provides 61 feet of true ground-following flex, and the close reel-to-cutter bar relationship ensures efficient heads-first crop flow over the entire 61-foot span of the header. The 61-foot gathering width is the ideal solution for controlled traffic farming. MacDon’s innovative upper cross auger system keeps the crop from getting held up on the ends for uninterrupted crop flow on 61 feet of gathering width, he says.

MacDon Industries, Winnipeg, Man.

www.MacDon.com

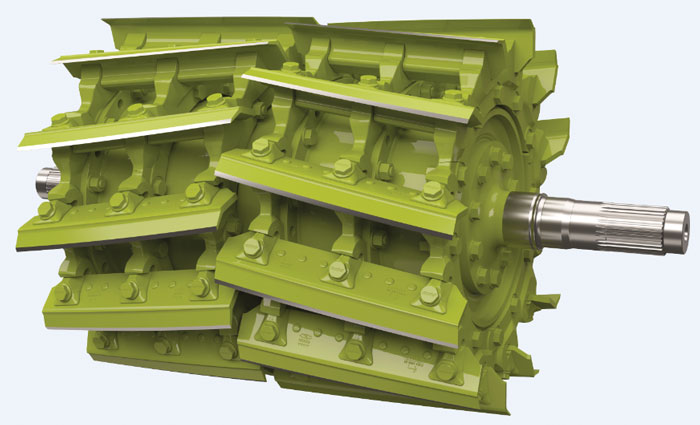

Claas of America V-FLEX Knife Drum (No. 234)

“The new Claas V-FLEX knife drum represents a significant advancement in forage harvesting technology,” says Tyler Roucka. “This innovative knife drum is engineered to be 2-3 dBA quieter than its predecessors.” Featuring a refined 10-degree knife angle, it offers a 1.5% increase in operational efficiency. The drum is equipped with 6 replaceable knife rings, allowing for flexible configurations — either installing all knives or using only half the section to achieve a longer cut length. The drum and knife-holding rings are designed with flexibility in mind, enabling easy swaps for different knife configurations based on customer preference. Additionally, the newly designed hook on the back of the knife holder is engineered to flex upon impact with large rocks, thereby mitigating the risk of costly damage. The knives themselves are enhanced with 20% more hard surface material, extending their wear life by 20% compared to its predecessors.

Claas of America, Omaha, Neb.

www.Claas.com

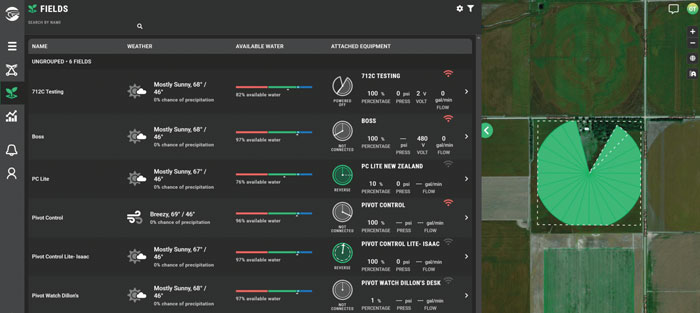

Lindsay FieldNET Advisor Whole Farm Water Management (No. 235)

Lindsay’s FieldNET Advisor digital irrigation scheduling product has been updated to 1) use remote sensing to calculate crop evapotranspiration and 2) allow growers to easily enroll their entire operation in 30 seconds or less. This benefits growers as they can easily adopt a digital water management solution for their entire operation that provides satellite imagery, weather, soil moisture predictions, and an irrigation recommendation that they can easily execute via their cell phone, says Lindsay’s Justin Gibson. Grower feedback has been extremely positive with this new update and we’ve seen significant growth in adoption due to the ease of use and increased confidence now that the product uses satellite imagery directly in the calculation of evapotranspiration.

Lindsay Corp., Omaha, Neb.

www.Nextgen.MyFieldNet.com